We are strong believers that not everything will fit into the conventional “standard†realms of products and having FDA bar stock material available in our iglidur® polymers allows the customer to be as creative as they desire. As a result, it allows customers from a large range of industries to have custom machined parts made for their applications. The food industry is one of the biggest industries in the UK, so it is no surprise that at igus® we have a large range of food approved stock bar and stock plates available and in stock. The variety of products that are used within the food

industry is vast and any that are in direct contact with food products need to

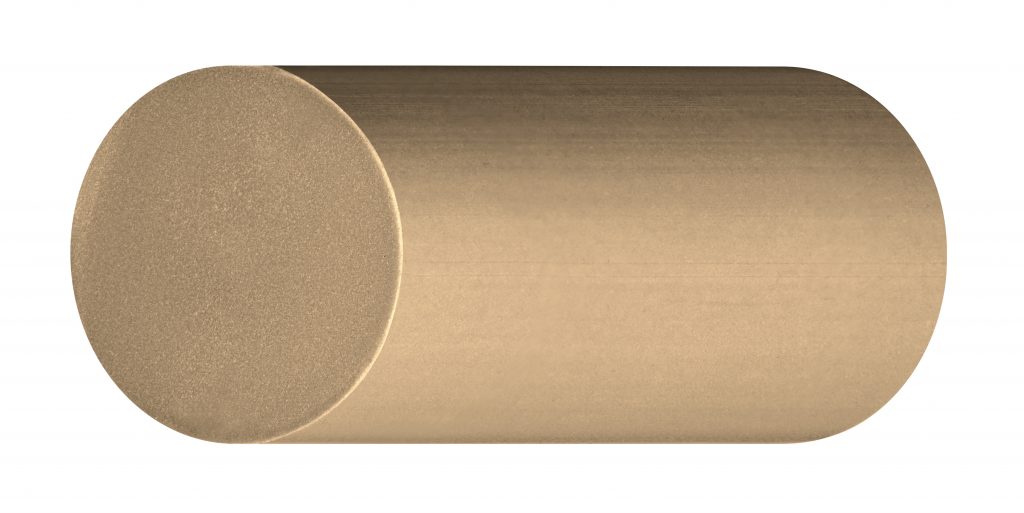

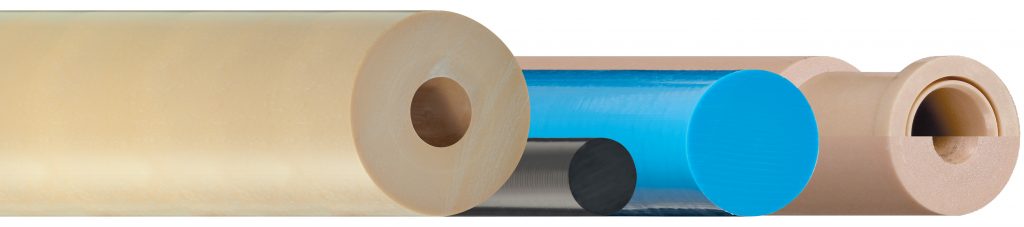

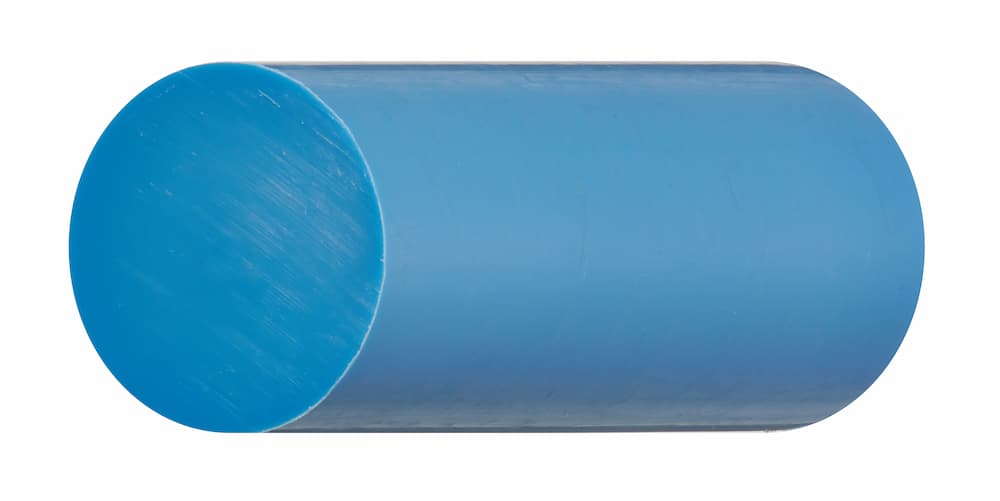

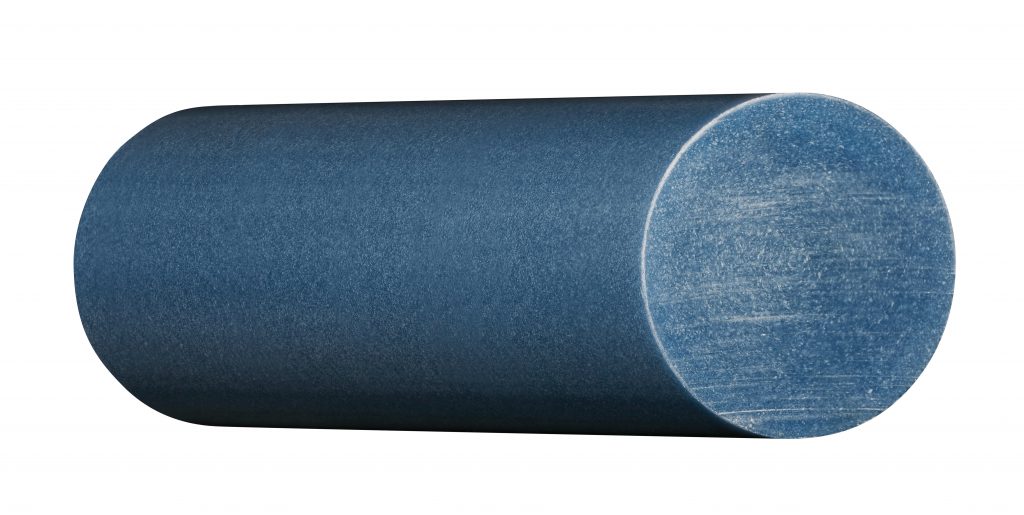

comply with FDA and EU-10/2011 regulations. FDA is abbreviated from Food & Drug Administration and is the body responsible for protecting public health by regulating human and animal drugs, medical devices, tobacco products and cosmetics. The EU-10/2011 regulation is slightly different. These regulations are specifically for plastic materials in contact with food. It is a complex matter how all of the products in our range have been approved by the PMA and have full certification.  The key iglidur® materials are: All of the above are available in both plastic rod and stock plate except A181, this however is only available in round bar. This allows us to cover the entire range of requirements: high temperature, high chemical resistance, low-cost, low moisture absorption and 3 of them are blue! This blue, low-cost material is perfect for applications where a high media resistance is required. It is lightweight, easy to machine and is compliant with EU regulation 10/2011 and is also FDA compliant. In bar form this material is available in 10mm diameter up to 100mm diameter. As standard it is available in metre lengths but can be cut to specific lengths. This is the same for all the materials. The plate comes in thicknesses of 10mm and 20mm. This material is comparable to iglidur® A180 in relation to its characteristics, however it is blue, similar to iglidur® A160. Again, this material  is compliant with both EU regulation 10/2011 and FDA. Our A180 material has one of the largest ranges of FDA- approved stock bar that we have. It comes in 10mm diameter right up to 100mm diameter and is also available in plate, 10mm and 20mm thick. The main difference with this material is that it is white. We machine this a lot for the food industry for aesthetics as opposed to the food contact element. The A350 material is one of the high- temperature materials. It is blue in colour, can withstand temperatures of +180°C and is highly resistant to chemicals as well. An added feature for this material is that not only does it have EU regulation 10/2011,it is also FDA- compliant and it complies with the fire prevention requirements of the Federal Aviation Administration of the USA (FAA) for aircraft interiors. Like the A180, the bar is available from 10mm up to 100mm diameter. This is the boss of the FDA materials. It withstands the highest temperatures (+250°C), is highly chemical resistant and is very hard wearing. This material has the same sizes available in bar form as A350. As mentioned at the beginning of this blog, not everything conforms to the “norm.†Having materials available to machine weird and wonderful designs allows food lines to continue running without expediential expense. With the igus® food- approved materials, you have the confidence that the production line is keeping customers safe. Watch the igus® product manager talk more about bar stock here. Construction Machinery External Parts Mold Construction Machinery External Parts Mold,Forklift Hood , Forklift Casing,Paving Machine Housing Jingchuang Automotive Design Co., Ltd , https://www.compoproducts.com

What materials do igus® offer in the FDA bar stock range?

The main features for each material

A160

A181 FDA bar stock material

A180 FDA bar stock material

A350 FDA stock bar material

A500 FDA stock bar material