As an essential piece of equipment, the press brake plays a pivotal role in metal sheet fabrication. It is mainly designed for achieving metal sheet precise bending and forming. It is widely used in various precision machinery industries such as automobile manufacturing, aerospace, electrical appliance manufacturing, etc., which can ensure the products’ precision and production efficiency. However, there is always a problem that the press brake won’t go up, troubling many sheet metal enterprises. This problem may not only cause production stagnation and delivery delays but also directly affect the quality of the workpiece, increasing unnecessary repair costs and production losses. Our passage aims to offer a comprehensive solving guide for this troublesome issue. We will delve into the various reasons why the press brake won’t go up, and combine the abundant sheet metal knowledge ranging from equipment maintenance, and operation regulations to malfunction troubleshooting, to talk about how to solve this problem, making the operation stable and efficient and the overall the procedure smooth and effective. Press brake is mainly composed of the following basic components: body frame, hydraulic system, electric control system, back gauge device, tooling (upper punch and bottom die), and worktable. The body frame is the basic structure of the equipment, the hydraulic system is responsible for the pressure required by bending, electricity control system can ensure the precision and automation degree of the equipment operation. The back gauge is designed for positioning the sheet, and the tooling determines the shape and size of the workpiece, while the workbench is designed for supporting and fixing the sheet to be processed. In metal fabrication processing, the press brake plays an important role, which is assisted by strong hydraulic pressure, and can precisely bend the flat metal sheet into the required 2D or 3D shapes through adjusting the angle and distance between the upper and bottom die, achieving the high efficient forming processing of the components. This process is of decisive significance for manufacturing various sheet metals, like boxes, shells, and brackets. The stability and lifespan of the press brake are mainly determined by daily maintenance. Work like regular lubrication, cleaning, checking, and replacing abrasive components can effectively avoid malfunction situations occurrence won’t go up because of aging, abrasiveness, blocking, etc. Besides, good habits of maintenance can ensure press brake precision, lower production errors, improve production quality, prolong the equipment lifespan, and reduce downtime and maintenance costs, which is beneficial for enterprises’ consistent and highly efficient production. Many problems occur in press brake operation, including precision errors due to lack of hydraulic system pressure, tooling worn or improper installation, and movement incoordination, the inaccurate position of the back gauge owing to electrical control system malfunction. Our passage is mainly focusing on one of the common situations--press brake won’t go up. When the press brake won’t go up, this may be caused by one of the key procedures in the equipment's inner step. This problem leads to the entire sheet metal processing process coming to a standstill, severely affecting the production efficiency and production quality. It is paramount to proceed with the initial diagnosis that the press brake won’t go up. The operator should troubleshoot according to the following procedures: Check whether the oil level of the hydraulic system is common or not and whether the oil leaks or oil blocks. Ensure the power supply and signal transmission of the electrical control system is smooth or not. Check the related button, switch, and contact working situation. Observe and test if the equipment has abnormal noise or vibration to check if the mechanical component is damaged or stuck. The reason for “press brake won’t go upâ€Â may be divided into two main types: mechanical and electrical problems. A mechanical problem is concerned with the components worn, torn, or blocked, like hydraulic cylinders, pistons, connecting rods, bearings, and so on, and seals failure and oil circuit blockage in the hydraulic system. Electrical problems are derived from the failure of electrical components like a controller, motor, relay, sensor, or poor contact, short circuit, open circuit, etc. in the power supply line. Ensuring safety is a priority to other tasks in press brake troubleshooting procedures. The operator must obey the related working regulations. For example, how to check the electrical in a power outage state, how to use specialized tools to touch the movement components directly instead of fingers, and set the warning signals before repairing to avoid other people operating incorrectly. Only obeying the safety regulations can solve the problem efficiently and ensure the operator's and equipment's safety. Shut down and ensure safety: the power supply must be cut off before maintaining any electrical issues to assure the operators’ safety. Preliminary judgment: judge the probable trouble area preliminarily according to failure phenomenon (equipment unstarting, unusual movement, alarm displaying). Detailed checking: check the probable malfunction area in detail. Check whether the connector is loose, the cable is damaged, and switches, relays, contactors, and other components are intact. Test and verify: use the test tools to test the suspected components singly or combinationly to ensure the failure source. Repair and replace: once the malfunction point is found, repair or replace the damaged electrical components in a timely, and restore the system's normal operation. Hardware diagnostic tools: such as portable oscilloscopes, digital multimeters, and infrared thermal imaging cameras, can be used to measure electrical parameters like voltage, current, and frequency, and check the circuit's moving state. Meanwhile, thermal imaging cameras can reflect the equipment's fever, helping to discover overheating or poor heat dissipation. Software diagnose systems: many modern press brakes and sheet metal equipment are equipped with inner malfunction diagnose software, which can monitor the system state and record false codes. The operator can quickly position the potential point of failure by reading false codes and warning information, and combining the equipment manual to do the preliminary analysis. Internet and communication diagnose tools: as for the equipment adopting a digital control system, and using specialized internet diagnose tools to check the stability of the communication links, ensuring the controller, sensor, and driver’s data transformed is abnormal. Remote diagnose service: some high-tech equipment offers a remote diagnose function, allowing the manufacturing technique teammates to be directly linked into the equipment control system through the internet, checking the equipment state, log files, and real-time data remotely, achieving quick and precise questions positioning. Our passage deeply talks about the troubleshooting and performance optimization of the press brake and sheet metal equipment, emphasizing analyzing the common issues and solutions of the hydraulic system, mechanical equipment, electrical system as well as software control. Through maintaining the good condition of the equipment and the high-level technique skills of the operator, you can largely minimize downtime, reduce repair costs, and improve stability and competitiveness. So, investing in maintenance and training is the key to ensuring the successful operation of the press brake and sheet metal equipment. Welcome to browse the ADH machine tool official website for info searching and machine purchasing. Titanium Cups,Titanium Camp Mug,Titanium Camping Cup,Titanium Backpacking Mug Bao Ji Titour Technology Co.,Ltd , https://www.cntitour.comI. Introduction

II. Understanding Press Brakes

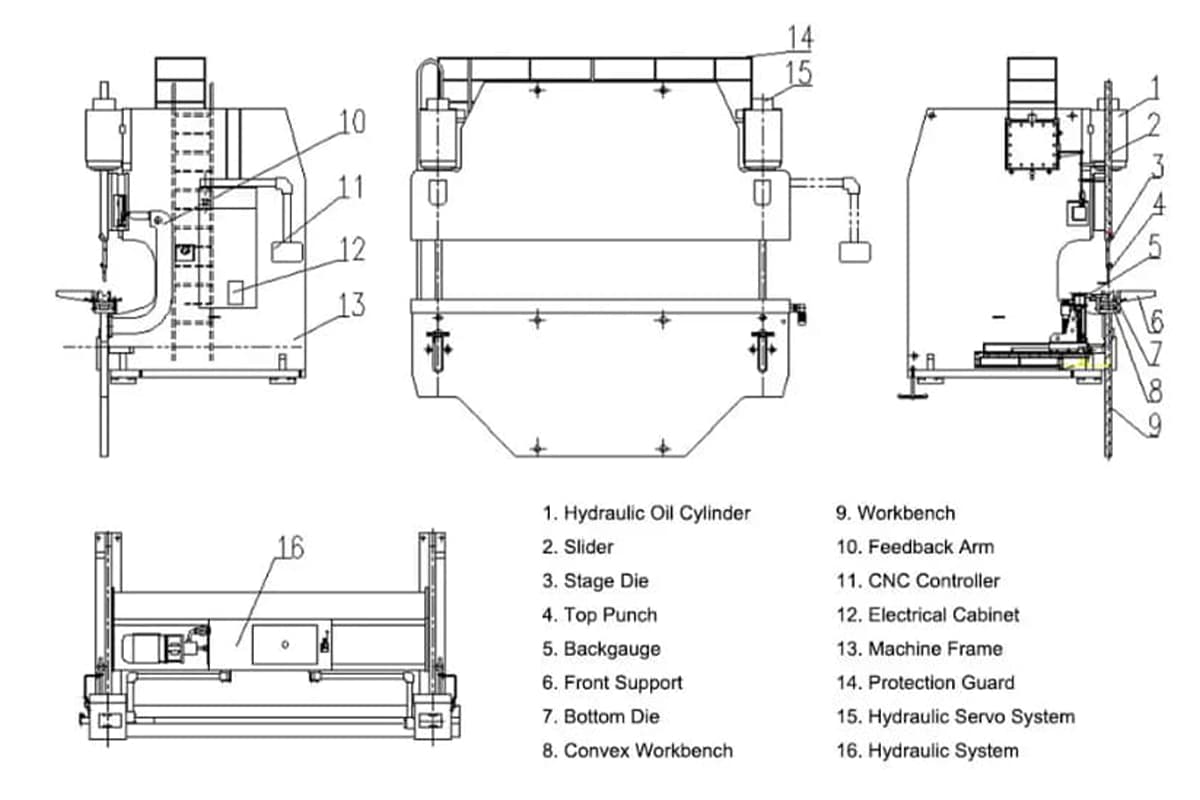

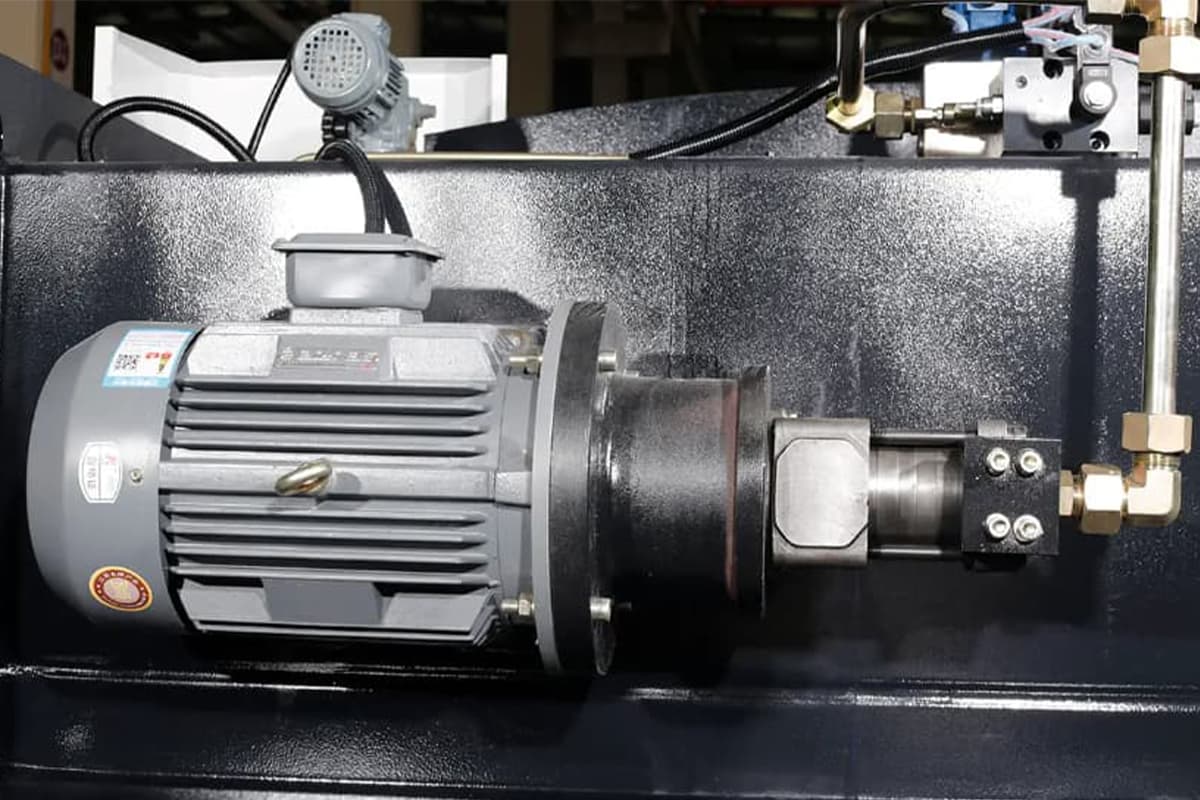

Basic Components of a Press Brake

How Press Brakes Function in Metal Fabrication

Significance of Press Brake Maintenance

III. Common Issues in Press Brake Operations

Overview of Common Press Brake Problems

Initial Diagnosis: Steps to assess the problem

Mechanical vs. Electrical Issues

Safety Precautions

IV. Mechanical Causes and Solutions

Hydraulic System Malfunctions

Mechanical Failures

Regular Maintenance Tips

V. Electrical Causes and Solutions

Electrical Component Failures

Troubleshooting Electrical Issues

Preventative Electrical Maintenance

VI. Software and Control System Errors

Identifying Software-Related Issues

Resetting and Updating Control Systems

When to Seek Professional Help for Software Problems

VII. Advanced Troubleshooting Techniques

Using Diagnostic Tools

Consulting Technical Support

VIII. Conclusion